ABOUT US

ABOUT US

Welcome to SY , your motor Vehicle fittings specialists!

SY Motor Vehicle Fittings was Co., Ltd was founded in Shanghai since 2018. We are one of the leading motor vehicle parts export enterprises in Shanghai, which specializes in Rubber、Plastic and Metal Products,Main for mudflaps,mudflap hanger,fender,fender brackets,Axle&Lug nut Cover,hinge,Pins.

We applied ISO9001:2000 international quality control system certification and certified,obtained the certificate of TS16949 and implemented KPI programs.Our sales Region include China, USA, Europe, Japan, South East Asia and other regions.

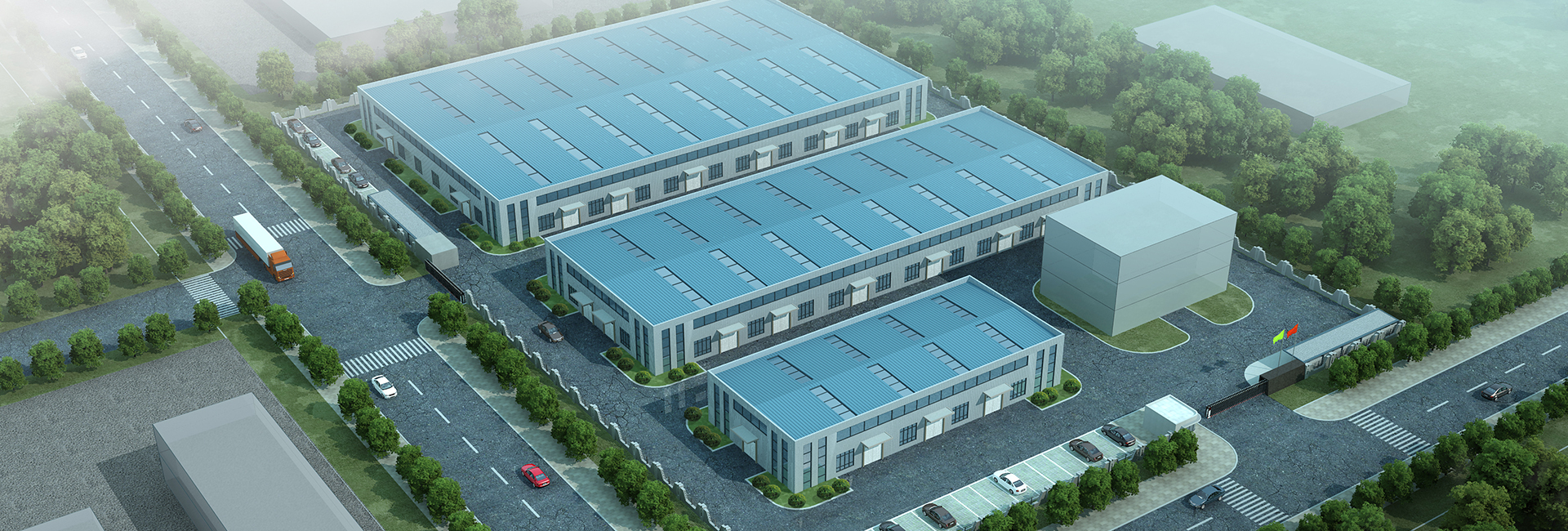

With a large scale factory in China, our manufacturing equipment, technology and design capabilities are comprehensive and limitless. Due to our large scale factory, in as little as an estimated 4 weeks your products can be ready for shipment. Every salesman is professional through systematic training.

In additional, we offer OEM and ODM service which are supported by our R&D team which has over years experience in this Industry. SY Motor Vehicle Fitting Co.,Ltd is dedicated to providing our customer with the most advanced technology available. We have been developed over hundreds safety products that conform to different standards. We have implemented astringent quality control standard to ensure our customers in this ever-changing global markets. Our company systems are designed to dramatically save our customer’s time and effort to find the right fittings.At SY ,we work diligently developing new material compositions and products for application in more fields. During this process,we carefully analyzes every step to ensure that our customers always to receive the best quality products. At SY , quality is our number one commitment.

We are a company committed to building long-term partnerships with our customers all around the world. Our goal is to be your primary source for all kinds of Traffic & Parking Safety products. In the future, we will comply with the stream of time, insist to provide assistance at any stage of your demand, and willing to become the leader of auto parts industry with you.

Department

Department

- R&D Center

- Production workshop

- Quality inspection workshop and experimental center

- Warehouse